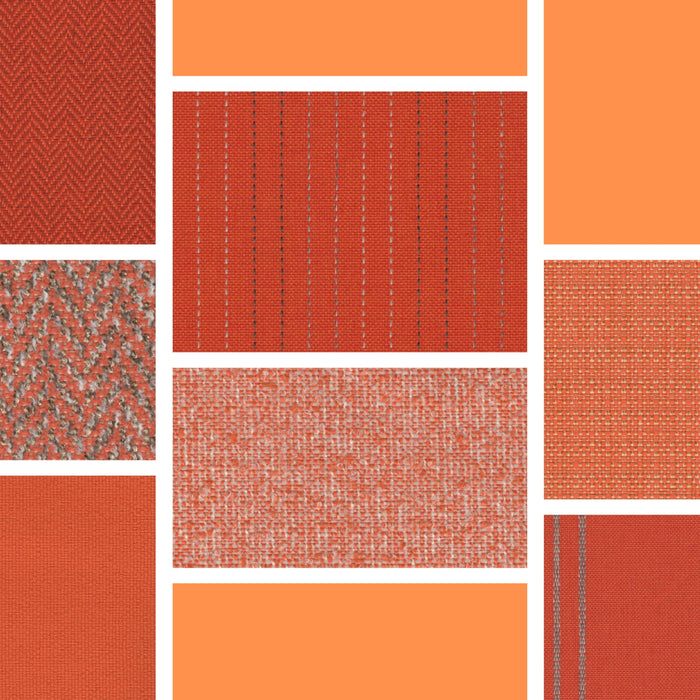

Understanding Double Rubs: The Key to Durable Upholstery Fabric

What Are Double Rubs? When exploring options for upholstery fabric, you'll frequently encounter the term 'double rub.' This is a crucial measure of a fabric's durability against wear and tear. The double rub count is determined using the Wyzenbeek Test,...